Want to learn about the different types of Japanese swords? Read on to find out about all the different types of Japanese swords and its history.

The samurai sword. A symbol of honor, discipline, and unwavering spirit. But did you know there’s more to these blades than just the katana? In the world of Japanese swords, there’s a rich history and variety waiting to be explored.

From the massive greatswords wielded by warriors on horseback to the elegant daggers carried by samurai, this guide will unveil the different types of Japanese swords and their fascinating stories.

So, unveil your inner samurai and dive into the art of the Japanese blade!

Types of Japanese Swords: Quick glance

| Types Of Japanese Swords | Description |

| Katana | A curved, single-edged sword with a long grip and circular or squared guard. Wielded by samurai as their primary weapon. |

| Wakizashi | A shorter sword, often the companion to the katana, with a similar design. Worn by samurai as a secondary weapon or for close-quarter combat. |

| Tanto | A dagger or short sword with a straight or slightly curved blade, primarily used for stabbing and slashing attacks. |

| Tachi | An older style of sword with a curved, single-edged blade longer than a katana. Worn suspended from the waist and used by cavalry for slashing attacks from horseback. |

| Uchigatana | A predecessor to the katana, characterized by a curved, single-edged blade and circular or squared guard. Used by samurai in warfare and eventually evolved into the katana. |

| Naginata | A polearm weapon with a curved blade mounted on a long wooden shaft. Wielded by female warriors for sweeping and striking techniques. |

| Yari | A spear-like weapon with a straight, double-edged blade attached to a wooden shaft. Used by foot soldiers in various formations. |

| Tsurugi | An early type of longsword with a straight blade, predating the katana. Influenced by Chinese and Korean sword designs. |

| Shirasaya | A style of mounting or scabbard with a plain wooden design, emphasizing the beauty of the blade. |

| Shinai | A bamboo practice sword used in the martial art of kendo to simulate the weight and feel of a real sword. |

| Gunto | Military swords mass-produced for officers of the Imperial Japanese Army and Navy during the early 20th century. |

| Yoroi-doshi | A specialized tanto designed to penetrate the gaps in samurai armor. |

| Tantō | A dagger-like sword with a straight or slightly curved blade, commonly used by samurai for utility and close-quarters combat. |

| Shikomizue | A sword concealed within a walking cane or staff, developed as a discreet weapon for samurai. |

| Ōdachi | An exceptionally long sword with a blade measuring over 90 centimeters. Wielded by skilled warriors on foot. |

| Shinken | “Real swords” forged using traditional methods and materials, adhering to ancient Japanese swordsmithing techniques. |

Page Contents

Types Of Japanese Swords

Katana

The katana is perhaps the most famous and iconic Japanese sword. It is a curved, single-edged blade with a circular or squared guard and a long grip to accommodate two hands.

The katana was traditionally wielded by samurai and was their primary weapon. It is renowned for its sharpness, balance, and cutting ability.

The katana has a length of approximately 60-70 centimeters and is suitable for both slashing and thrusting techniques.

Wakizashi

The wakizashi is a shorter sword often referred to as the companion sword to the katana. It has a similar design with a curved, single-edged blade but is smaller in size, typically measuring between 30-60 centimeters in length.

The wakizashi was commonly worn by samurai as a secondary weapon or for close-quarter combat. It was also used for ceremonial purposes and as a symbol of social status.

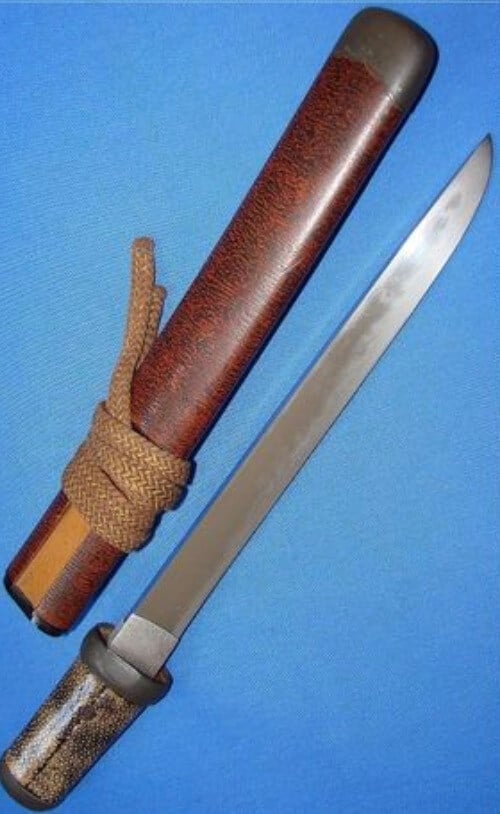

Tanto

The tanto is a dagger or short sword with a straight or slightly curved blade, measuring less than 30 centimeters in length.

It was primarily used for stabbing and slashing attacks in close combat. Tanto blades varied in design and purpose, ranging from battlefield weapons to decorative pieces. They were also employed in traditional Japanese rituals and ceremonies.

Tachi

The tachi is an older style of Japanese sword that predates the katana. It has a curved, single-edged blade, similar to the katana, but is longer and intended to be worn suspended from the waist.

The tachi was primarily used by cavalry during battles and was designed for slashing attacks from horseback. It later evolved into the uchigatana, which eventually became the katana.

Uchigatana

The uchigatana is a predecessor to the katana and is characterized by its curved, single-edged blade and circular or squared guard. It has a slightly shorter grip compared to the katana and was developed during the Heian period.

The uchigatana was primarily used by the samurai class and saw extensive use in warfare. Over time, it underwent various refinements, leading to the development of the katana.

Naginata

The naginata is a polearm weapon with a curved blade mounted on a long wooden shaft. It is similar to a glaive or halberd. The naginata was primarily wielded by female warriors, known as “onna-bugeisha,” who played a crucial role in defending Japanese households and castles.

The long reach of the naginata allowed for effective sweeping and striking techniques, making it a formidable weapon on the battlefield.

Yari

The yari is a spear-like weapon with a straight, double-edged blade attached to a wooden shaft. It was commonly used by foot soldiers, especially during feudal Japan. The yari was versatile and effective in both thrusting and slashing attacks.

It played a significant role in warfare and was employed in various formations by samurai warriors.

Tsurugi

The tsurugi is a double-edged longsword with a straight blade, often characterized by a pronounced central ridge. It is one of the earliest types of Japanese swords and has a history dating back to ancient times.

The tsurugi was influenced by Chinese and Korean sword designs and was used during the Kofun period in Japan. While not as prominent as other types of Japanese swords, the tsurugi holds historical significance as an early precursor to the iconic katana.

Shirasaya

The shirasaya is not a specific type of sword but rather a style of mounting or scabbard used for Japanese swords. It features a plain wooden scabbard and handle without elaborate decorations or fittings.

The simplicity of the shirasaya design emphasizes the beauty of the blade itself. Swords stored in shirasaya are often considered collectible pieces or displayed for their aesthetic value.

Shinai

The shinai is not a traditional Japanese sword, but rather a practice weapon used in the martial art of kendo. It is a bamboo sword designed to simulate the weight and feel of a real sword while minimizing the risk of injury.

The shinai consists of four bamboo slats held together by leather or string and is used in training and competitive matches. Kendo practitioners learn swordsmanship techniques, discipline, and respect through the use of the shinai.

Gunto

Gunto refers to a type of Japanese military sword used during the early 20th century, particularly in the World War II era. These swords were mass-produced for officers of the Imperial Japanese Army and Navy.

The gunto swords have a distinctive handguard design with a knuckle bow and a plain, non-traditional blade.

While they lack the artistic craftsmanship of earlier swords, gunto blades hold historical significance as symbols of the military during a transformative period in Japanese history.

Yoroi-doshi

The yoroi-doshi, also known as “armor piercer,” is a specialized type of tanto designed to penetrate the gaps in samurai armor. It has a short and stout blade with a thick spine and a strong point, allowing it to thrust through the protective armor plates.

The yoroi-doshi was primarily used by samurai warriors as a backup weapon during close combat when the main weapon was rendered ineffective.

Shikomizue

The shikomizue, meaning “prepared cane,” is a unique type of Japanese sword concealed within a walking cane or staff. It was developed during the Edo period as a discreet weapon for samurai who needed to hide their swords due to strict regulations or to maintain an element of surprise.

The shikomizue featured a removable blade hidden within the cane, making it a practical and inconspicuous self-defense tool.

Ōdachi

The ōdachi, also known as “great sword” or “nodachi,” is an exceptionally long Japanese sword with a blade measuring over 90 centimeters in length. It was primarily used by skilled warriors on foot, such as samurai infantry or guardsmen.

The ōdachi’s extended reach and cutting power made it effective against multiple opponents or when facing enemies on horseback. Due to its size, the ōdachi was typically wielded with two hands.

Shinken

Shinken refers to a “real sword” that is forged using traditional methods and materials, adhering to the ancient techniques of Japanese swordsmithing. These swords are crafted with meticulous attention to detail and are highly valued for their authenticity and quality.

Shinken swords are often used in martial arts training, test cutting (tameshigiri), and as prized collectibles by enthusiasts who appreciate the historical significance and craftsmanship behind them.

How Japanese Swords Are Made?

Japanese swords are made with traditional steel called tamahagane. The first step involves smelting iron sand with charcoal in a furnace. High and low carbon content is extracted and further purified, heated, hammered, and folded a dozen times to form strong layers. The blade is then coated with charcoal and clay mix and heated. The sword is then dipped in water to attain a curve and then polished. Lastly, the sword is mounted and decorated.

It took months to just make a single blade by the Japanese craftsman where they worked dedicated to bring out the best in their weapons. These craftsmen had a perfect knowledge on chemical metallurgy as well as swordsmithing.

The process was quite extensive and dozens of labourers would be involved in the entire process (sometimes to just make one). That’s how Japanese swords are made, with dedication and minute detalings.

Well, the most important thing is to have the chemical knowledge as without that the entire method of swordsmithing is a waste.

Now, let’s move forward, step by step on how Japanese swords are made!

- Step 1: Steel Making

In this process, the tatara is made by smelting iron sand that contains one iron ore. It is done with charcoal in a huge clay furnace.

The next step is quite important and runs for 72 hours without any intervention or pause. The swordsmiths once realise that it’s the correct temperature, they feed iron sand and charcoal as per the requirements.

The first step is really crucial to move forward to knowing how Japanese swords are made.

- Step 2: Steel Sorting

This step is done after the 72 hours of extensive smelting process. In the second step of how Japanese swords are made, the blacksmiths break the clay furnace to extract tamahagane.

From the tamahagane, they break further to separate the mass of steel keeping in mind the carbon content. High carbon steel will give the razor with sharp blades whereas the low carbon content one is meant for toughness.

Any form (high or low) of carbon content missing can result in sword abnormalities like dullness or brittle sword. Therefore, both are equally important.

- Step 3: Steel Purification

The is one of the most important steps of how Japanese swords are made. All the impurities and slag is drawn away in this step.

The decent pieces of tamahagane are sent to be beaten up by hammer for over 16 times by heating, hammering and folding continuously. This is done to combine the iron and carbon for bringing in qualities like sharpness, toughness etc.

- Step 4: Blade Forging

After the swordsmith removes the impurities the next step is forging the samurai swords.

The high carbon steel is heated to be forged into a U shaped channel whereas the low carbon steel is heated to be forged into a strip that fits inside the U shaped channel.

After being separately forged, they are forged together where the outer shell of steel gives the sharpness while the inner one is meant for toughness and durability.

This process might seem a little tedious but it’s done with great patience. This is how Japanese swords are made with forging carbon and steel.

- Step 5: Blade Coating

Blade coating is done after forging where a deep layer of clay and charcoal mixture is applied on the upper side and back edge. This is only for the primary coating and gives a wavy edge to the sword that is popularly called hamon.

This blade is then fired at just 1500 degrees fahrenheit or 815 degrees celsius. The degree of heat shouldn’t be any less or any more. There’s a risk of cracking or damage if the heat is excess.

This is how Japanese swords are made at this stage.

- Step 6: Blade Curving

If you are wondering how Japanese swords are made with perfect curves then here is your answer.

After heating the blade is pulled out of the fire and dipped in water. The change in temperature causes the blade to bend and give its signature curve.

- Step 7: Blade Polishing

How Japanese swords are made with perfect shine? This is a crucial stage and involves several sub steps to make the polish perfect.

After being fully forged, it is polished with a few grinding and polishing stones to sharpen the razor blade in the polisher. This process is not as simple as it seems as it takes weeks and months to do it.

If the polisher is inexperienced, the blade’s geometry can be disturbed or it can wear down too much steel which can destroy the sword’s cultural, functional and historic significance. This is because any extra amounts of oil leftovers can lead to corrosion and rusting.

The salts present in the polishing oil can lead to the development of molds and mildew. Polishing the blade improves the blade’s clarity, aesthetic, and characteristics.

One can look at the blade and talk about how the cutting edge was cooled, the carbon content of the steel and how well they’re polished.

- Step 8: Blade Mounting

The blade is then mounted with a decorative guard and then carpenters fit the blade in a scabbard.

There are a few artisans that decorate it and then the handle is made with leather, stone or gold.

This step is as important as the first few steps of making the blade. It is considered a piece of art. When looking at how are Japanese swords made, this step is quite unique and meticulously done.

- Step 9: Final Inspection

This is the last step of how Japanese swords are made. After the decoration, handle and everything, the sword is handed over to the swordsmith to check if everything is perfect.

Once it is declared good for usage, it is handed over to the Samurai or the new master.

Where Can I Watch How Japanese Swords Are Made?

If you’re really interested in seeing how Japanese swords are made you should definitely visit The Japanese Sword Museum in Tokyo.

This museum showcases the art of how Japanese swords are made. It is run by the Society for the Preservation of Sword Arts and gives a deep insight on Japanese weaponry.

It contains many swords that have special status or hold cultural significance. The Occupation Forces tried to destroy the swords after WWII but somehow it’s safe and saved.

Another museum, The Bizen Osafune Sword Museum. The museum has an amazing collection of swords from the past and is one of its kind.

You can also attend seminars and workshops that show you how Japanese swords are made and maintained, various people involved in building the Japanese weapon and other various components that one is interested to know.

You can also ask questions if you have doubts and learn so much more. There are workshops where visitors can see how Japanese swords are made from tamahagane, the traditional Japanese steel.

There are limited dates and timings of these workshops so make sure you book your slot in advance.

What are the 3 samurai swords called?

The three main samurai swords are the katana, wakizashi, and tanto. The katana is the longest and most well-known, with a curved, single-edged blade, circular or squared guard, and a long grip for two-handed use.

The wakizashi is a shorter companion sword to the katana, typically measuring between 30 to 60 centimeters, and served as a backup weapon or for close-quarter combat.

The tanto is a dagger or short sword with a straight or slightly curved blade, usually less than 30 centimeters in length, primarily used for stabbing and slashing attacks. Together, these three swords formed the iconic arsenal of the samurai warriors.

What are the 5 most famous swords of Japan?

The five most famous swords of Japan, often referred to as the “Five Swords Under Heaven” or “Gokaden,” are legendary for their historical significance and exceptional craftsmanship.

They include Kogarasu Maru, Onimaru, Mikazuki Munechika, Dojigiri Yasutsuna, and Masamune’s Honjo Masamune. Kogarasu Maru is said to have been crafted by legendary swordsmith Amakuni during the 8th century.

Onimaru, forged by Awataguchi Kuniyoshi, is known for its mythical origins and association with the legendary hero Yoshitsune.

Mikazuki Munechika, crafted by Sanjo Munechika, is one of the oldest existing swords and is steeped in folklore. Dojigiri Yasutsuna, associated with the hero Yoshitsune, is renowned for its cutting ability.

Lastly, Honjo Masamune, created by the revered swordsmith Goro Nyudo Masamune, is considered a national treasure of Japan and represents the pinnacle of Japanese swordsmithing.

How many types of katanas are there?

In general, there is only one type of katana, which is the iconic Japanese sword with a curved, single-edged blade, circular or squared guard, and a long grip for two-handed use.

The katana is renowned for its craftsmanship, balance, and cutting ability.

However, within the category of katana, there can be variations in terms of design, period of production, and specific characteristics.

These variations can include variances in blade shape, length, curvature, fittings, and the school or region of the swordsmith. These differences result in unique individual katanas with their own distinct qualities, but they are all still considered within the general category of katana.

So while there are no specific “types” of katanas in the same way there are distinct types of Japanese swords, each individual katana can have its own unique features and history.

How many types of swords are there in Japan?

There are numerous types of swords in Japan, each with its own distinct characteristics and historical significance.

Some of the main types include the katana, wakizashi, tanto, tachi, naginata, yari, tsurugi, shirasaya, shinai, gunto, yoroi-doshi, shikomizue, ōdachi, and shinken. These swords vary in terms of blade shape, size, purpose, and cultural context.

From the renowned katana wielded by samurai to the elegant tanto dagger and the ceremonial ōdachi, the diverse array of Japanese swords reflects the rich heritage and craftsmanship of the nation’s swordmaking tradition.

What is a straight katana called?

A straight katana is commonly referred to as a “chokutō.” The term “chokutō” translates to “straight sword” in Japanese. While the katana is typically known for its curved blade, the chokutō deviates from this characteristic and features a straight blade design.

The chokutō was used during earlier periods of Japanese history, such as the Kofun and Heian periods, before the curved katana became more prevalent.

The chokutō holds historical significance as one of the predecessors to the iconic curved swords that are synonymous with the samurai warrior tradition.

What is a half katana called?

A half katana is commonly referred to as a “handachi.” The term “handachi” translates to “half-tea” in Japanese, which is thought to describe the length of the sword being roughly half the size of a traditional katana.

The handachi features a shorter blade compared to a standard katana, typically measuring around 60-75 centimeters in length.

It also has a distinct hilt style, with a shorter handle wrapped in the traditional katana style but fitted with a tsuba (guard) that is typically seen on a wakizashi. The handachi was used during the Muromachi period and is considered a transitional style of sword.

What is a giant katana called?

A giant-sized katana is commonly referred to as an “ōdachi” or “nodachi.” Both terms are used interchangeably to describe an exceptionally long Japanese sword. The term “ōdachi” translates to “great sword” in Japanese, while “nodachi” can be translated as “field sword” or “field cleaver.”

These swords typically have a blade length of over 90 centimeters (35 inches) and are significantly longer than the standard katana.

The ōdachi/nodachi was primarily used by skilled warriors on foot and offered increased reach and cutting power. Due to their size, these swords were typically wielded with both hands.

Why carry 2 katanas?

Carrying two katanas, known as “daishō,” symbolized a samurai’s status and readiness. The longer katana was the primary weapon for open combat, while the shorter wakizashi served as a backup and was used in close quarters.

The daishō showcased a samurai’s preparedness, adherence to the warrior code, and distinguished them from the common people. It held ceremonial and symbolic significance and provided versatility in combat.

What is a double edge katana called?

A double-edged katana is commonly referred to as a “ryōtō” or “ryōkatsujin.” These terms translate to “two swords” or “double sword” in Japanese.

A ryōtō katana features a blade with edges on both sides, allowing for cutting and slashing techniques from either direction. Unlike the standard katana, which has a single cutting edge, the ryōtō katana offers the advantage of versatility in combat, as the wielder can utilize both edges effectively.

The ryōtō katana is less common than its single-edged counterpart but showcases the ingenuity and adaptability of Japanese sword craftsmanship.

What is a katana without a curve called?

A katana without a curve is commonly referred to as a “shinken” or a “tachi.” The term “shinken” translates to “real sword” in Japanese, emphasizing its authenticity and functionality as a weapon.

A shinken katana typically has a straight blade, lacking the characteristic curve associated with traditional katana.

On the other hand, the term “tachi” refers to a historical type of sword that predates the katana. Tachi swords are characterized by their longer length and often have a straight or slightly curved blade. They were worn suspended from the waist, with the cutting edge facing down, and were primarily used by samurai warriors on horseback.

Both the shinken and tachi represent variations of the katana design with a straighter blade, either in terms of historical context or functional purpose.

What is the blood groove on a katana called?

The blood groove on a katana is commonly referred to as a “hi.” The term “hi” translates to “groove” or “furrow” in Japanese. The purpose of the hi is often misunderstood, as it is not primarily intended for allowing blood to flow out of a wound.

Instead, the hi serves multiple functions, including reducing the weight of the blade, enhancing the balance of the sword, and creating audible feedback during sword swings.

Additionally, the hi can create slight air turbulence, which may assist in preventing the blade from getting stuck when withdrawing it from a body or other objects.

What is a dagger katana called?

A dagger-like katana is commonly referred to as a “tanto.” The term “tanto” translates to “short sword” or “dagger” in Japanese.

While the katana is typically characterized by its longer length and two-handed grip, the tanto is a smaller blade with a straight or slightly curved edge. Tanto blades are typically around 15-30 centimeters (6-12 inches) in length and are designed for close-quarters combat and stabbing techniques.

They were commonly used by samurai warriors as a backup weapon or for utility purposes, such as cutting through armor gaps or performing tasks that required precision and control.

What is the coolest Japanese sword?

The coolest Japanese sword must be the Honjo Masamune. The Honjo Masamune is an exceptional katana that is considered one of Japan’s national treasures. It was crafted by the renowned swordsmith Goro Nyudo Masamune during the 13th century.

What makes the Honjo Masamune particularly fascinating is its storied history and the aura of legend surrounding it. This sword has been passed down through generations and is associated with notable figures and historical events.

Its exquisite craftsmanship and symbolic significance as a revered masterpiece of Japanese swordmaking contribute to its reputation as one of the coolest Japanese swords.

What is the oldest Japanese sword?

The oldest known Japanese sword is the “Kogarasu Maru.” Its name translates to “Little Crow” or “Small Crow” in English.

The Kogarasu Maru is attributed to legendary swordsmith Amakuni, who is said to have lived in the 8th century during the Heian period. The sword is believed to have been forged around the late 7th century, making it over 1,300 years old.

While the exact whereabouts of the original Kogarasu Maru are unknown, there are historical records and references to its existence. It is mentioned in ancient Japanese texts and revered for its mythological origins.

The sword is renowned for its importance in the development of Japanese swordmaking techniques and serves as a significant artifact of Japan’s early swordsmithing traditions.

How are Japanese samurai swords made?

Japanese samurai swords are made with special Japanese steel called tamahagane and smeted with different carbon concentrations.

Why Japanese swords are so expensive?

Samurai swords are expensive because of how Japanese swords are made. They require utmost skill and dedication and each of them can take more than 18 months to create. The blades alone can cost more than 1000 dollars. This traditional sword-making process has been going on for centuries and is still the same.

How are samurai swords so sharp?

Samurai swords are so sharp because they’re made with two types of tamahagane that are high content carbon which gives razor-sharp edges and toughness respectively. It is heated, hammered, and repeatedly folded a couple of times to retain strength and durability.

Conclusion

Japanese swords, with their diverse types and rich history, encapsulate the essence of Japanese culture, martial arts, and craftsmanship.

Each sword type holds its own purpose, whether it be for combat, ceremonial use, self-defense, or symbolic representation.

The artistry and skill involved in creating these blades have elevated them to more than just weapons, but as revered cultural artifacts and powerful symbols of Japan’s warrior heritage.

Also Read: